The science behind optical measurement: how it works

The science behind optical measurement: how it works

Blog Article

Understanding How Optical Dimension Systems Enhance Top Quality Control Processes

When you're aiming to improve quality control processes, recognizing optical dimension systems is necessary. These modern technologies provide specific, non-contact measurements that can transform your assessment approaches. By leveraging innovative strategies, you can streamline procedures and lessen mistakes. Exactly how exactly do these systems integrate right into existing operations, and what advantages do they bring? Allow's explore the crucial aspects that make optical measurement a game-changer in top quality management.

The Fundamentals of Optical Measurement Equipments

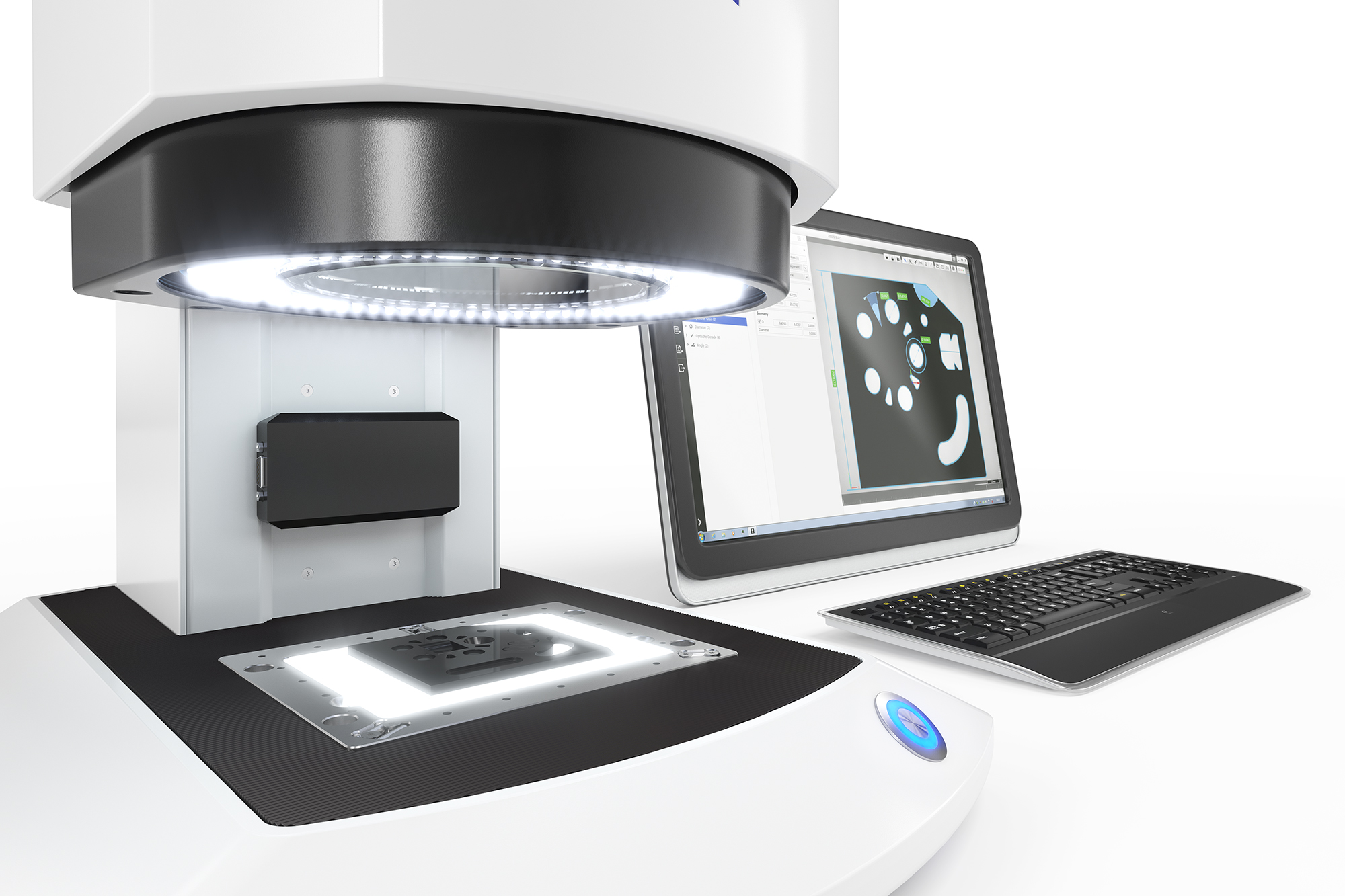

Optical dimension systems play an important role in assuring product top quality across different sectors. These systems use light-based innovations to collect specific information about physical features, such as dimensions, surface area coating, and color. By utilizing sensing units, cameras, and lasers, you can accomplish non-contact dimensions that reduce the danger of harmful delicate items.

Recognizing the principles of these systems is fundamental for effective quality assurance. They run on principles like diffraction, refraction, and representation, permitting you to analyze numerous materials and forms. The accuracy and rate of optical measurements enable real-time tracking, which helps you identify flaws early in the manufacturing procedure.

Furthermore, these systems can be incorporated with software application for enhanced information evaluation, creating a comprehensive quality administration method. By leveraging optical dimension systems, you not only enhance performance however also ensure your items meet rigorous high quality criteria, inevitably improving consumer complete satisfaction.

Kinds Of Optical Dimension Technologies

Various kinds of optical dimension technologies are readily available, each designed to meet specific requirements in quality assurance. You could encounter laser triangulation, which gauges distance by evaluating the angle of a shown laser beam. This innovation is suitable for capturing specific dimensions in 3D area.

An additional alternative is structured light, where you predict a collection of light patterns onto a surface to produce an in-depth 3D version. This approach works well for intricate geometries.

Then there's interferometry, which can identify minute changes in surface area profiles by assessing the disturbance patterns of light waves. This is especially beneficial for applications calling for nanometer accuracy.

You might additionally consider optical comprehensibility tomography, which provides high-resolution pictures of internal attributes without harming the item. Each modern technology offers different demands, so picking the best one is crucial for attaining highest control outcomes.

Secret Benefits of Optical Measurement in High Quality Control

When it pertains to quality assurance, leveraging optical measurement innovations can considerably enhance precision and effectiveness. These systems enable you to record thorough dimensions swiftly, decreasing the time required for evaluations. You'll notice that optical dimensions can recognize even the smallest flaws that could go undetected with conventional methods, guaranteeing item uniformity.

Additionally, using optical dimension systems typically leads to decreased waste and remodel, as you capture problems early in the manufacturing process. You'll additionally appreciate the non-contact nature of lots of optical methods, which lessens damage to delicate parts during evaluation. This flexibility allows for a broader series of applications throughout various materials.

With real-time information collection, you can make informed decisions promptly, enhancing your high quality guarantee procedures (optical measurement). Ultimately, integrating optical measurement right into your quality control method not just boosts efficiency yet also improves consumer satisfaction by providing higher-quality items continually

Exactly How Optical Dimension Equipment Improve Accuracy and Precision

Optical measurement systems increase accuracy and accuracy by boosting dimension resolution, enabling you to detect even the smallest variants. With real-time information evaluation, you can make instant modifications and choices, guaranteeing your procedures remain on track. This mix not just boosts item top quality yet also improves your quality assurance efforts.

Improved Measurement Resolution

By leveraging sophisticated technologies, optical measurement systems significantly enhance dimension resolution, leading to improved accuracy and accuracy in high quality control. You'll see a considerable distinction in the clarity of measurements, permitting you to determine also the tiniest discrepancies from specifications. Inevitably, boosted dimension resolution not only improves product top quality yet additionally enhances resource use, ensuring that you fulfill customer expectations continually.

Real-Time Information Analysis

Although traditional dimension systems often depend on delayed information processing, real-time data evaluation in optical dimension systems transforms the means you keep an eye on high quality. You'll experience improved precision since you can quickly contrast measurements against predefined standards. In addition, real-time data helps you gather useful insights over time, adjust your high quality control processes.

Incorporating Optical Measurement Into Existing High Quality Control Processes

Integrating optical measurement right into your existing quality control processes can substantially enhance accuracy and efficiency. By integrating optical measurement systems, you can enhance data collection, reducing human mistake while our website enhancing the rate of examinations. Start by identifying vital points in your manufacturing line where optical dimensions will give the most value.

Following, train your group on the brand-new technology, guaranteeing they recognize just how to utilize the systems efficiently. This training will assist them translate results promptly and properly.

You ought to likewise establish a protocol for integrating optical data into your existing top quality monitoring software application. This assimilation enables for real-time analytics and reporting, enhancing decision-making.

Routinely assess the data and feedback from your team to recognize any locations for enhancement. With these steps, you'll not just enhance your top quality control procedures yet likewise cultivate a society of continuous improvement within your organization.

Case Studies: Successful Execution of Optical Measurement Systems

In this area, you'll explore just how optical dimension systems have transformed high quality control in sectors like aerospace and automobile manufacturing - optical measurement. You'll see real-world instances of just how these technologies improved precision and efficiency. These case researches highlight the view website tangible advantages of integrating optical systems into manufacturing processes

Aerospace Industry Applications

As the aerospace sector faces increasing needs for accuracy and effectiveness, firms are turning to optical measurement systems to boost their quality control processes. A leading airplane producer integrated optical dimension innovation to check turbine blades, lowering inspection time by 50% while boosting accuracy.

Automotive Production Success

Optical dimension systems have likewise made i thought about this significant strides in the auto manufacturing market, where precision is vital to lorry performance and safety. BMW incorporated optical dimension for body assembly, making certain elements fit completely, which decreased rework and increased production efficiency. These situation research studies demonstrate exactly how optical measurement systems empower you to achieve tighter tolerances, lessen waste, and raise overall product top quality.

Future Patterns in Optical Measurement and Quality Assurance

While developments in innovation proceed to improve the manufacturing landscape, the future of optical dimension and quality assurance looks encouraging - optical measurement systems. You'll see a substantial change towards automation and AI combination, enabling systems to assess information in real-time. This indicates quicker decision-making and decreased human error, eventually improving product top quality

In Addition, as 3D imaging modern technology boosts, you'll take advantage of even more precise measurements of complicated geometries, making it simpler to preserve limited tolerances. The increase of cloud-based remedies will also permit you to gain access to information from another location, facilitating partnership and simplifying operations.

Furthermore, sustainability will certainly play a vital duty in future developments. Anticipate optical dimension systems to concentrate on power performance and waste decrease, aligning with international environmental goals. By embracing these fads, you can assure your quality assurance processes remain innovative, assisting your company grow in a progressively competitive market.

Frequently Asked Inquiries

What Industries Benefit The Majority Of From Optical Measurement Solutions?

You'll discover industries such as production, aerospace, and auto benefit most from optical dimension systems. These fields rely on specific dimensions for high quality assurance, guaranteeing items fulfill rigorous criteria and boosting general functional effectiveness.

Just how Do I Pick the Right Optical Measurement System?

To select the best optical dimension system, evaluate your certain needs, think about the type of measurements you call for, assess the system's precision, and ensure it fits your budget and operational requirements.

What Prevail Difficulties in Executing Optical Measurement Solutions?

You'll encounter obstacles like integration with existing systems, guaranteeing exact calibration, educating staff properly, and managing expenses. Identifying these obstacles early helps you establish strategies to conquer them and efficiently apply optical dimension systems.

Exist Training Resources Available for Optical Measurement Technologies?

Yes, there're numerous training sources available for optical measurement innovations. You can find on the internet courses, webinars, and workshops supplied by industry professionals or companies. These resources can help you effectively carry out and utilize these advanced systems.

Just How Do Optical Dimension Solutions Compare to Standard Measurement Methods?

Optical dimension systems provide better precision and speed contrasted to standard techniques. They reduce human mistake, make it possible for non-contact measurements, and give real-time data analysis, making them much more reliable for different applications in top quality control.

Conclusion

Optical measurement systems improve accuracy and precision by improving measurement resolution, allowing you to spot even the tiniest variations.By leveraging innovative modern technologies, optical measurement systems considerably enhance measurement resolution, leading to improved accuracy and accuracy in quality control.Although typical measurement systems commonly rely on postponed data handling, real-time data analysis in optical measurement systems changes the way you monitor quality.As the aerospace market faces boosting needs for precision and effectiveness, business are turning to optical dimension systems to enhance their quality control procedures. How Do Optical Measurement Solutions Compare to Standard Measurement Approaches?

Report this page